I was listening to a podcast recently and heard that some of the most expensive repairs are the result of sand getting into your gear. Traveling to the Caribbean, I am familiar with the fact that sand gets everywhere. I have learned not to change lenses at the beach, and am careful in cleaning lenses afterwards so as not to grind bits of sand into the lens coatings. Having just invested in a very nice tripod (read more about the tripod I selected here), I wanted to do what I could to minimize sand and seawater getting into the locks. In the past, I had resorted to using plastic bags held in place with hairbands to cover the legs when I was on the beach. After searching for a more professional setup, I decided that I needed to make my own solution. I read up on how to sew neoprene, and decided it was time to sew my own neoprene tripod leg covers.

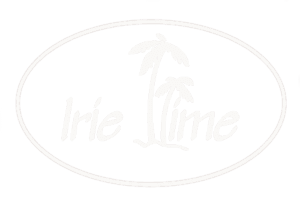

First, as for materials, I used neoprene, which is essentially foam rubber sandwiched between pieces of stretchy polyester fabric. Neoprene isn’t just basic black anymore. If you search online, you’ll see that it is now readily available in a variety of colors and patterns. I am a Mood Fabrics customer, so I went to their website and found 148 choices. I chose a 2.5mm thick neoprene with navy blue on one side and lime green on the other. In reading up on sewing neoprene, I read that if you go thicker than 3mm, it is extremely difficult to sew on a home sewing machine. I selected some navy blue, heavy duty polyester thread, and a needle designed for sewing leather.

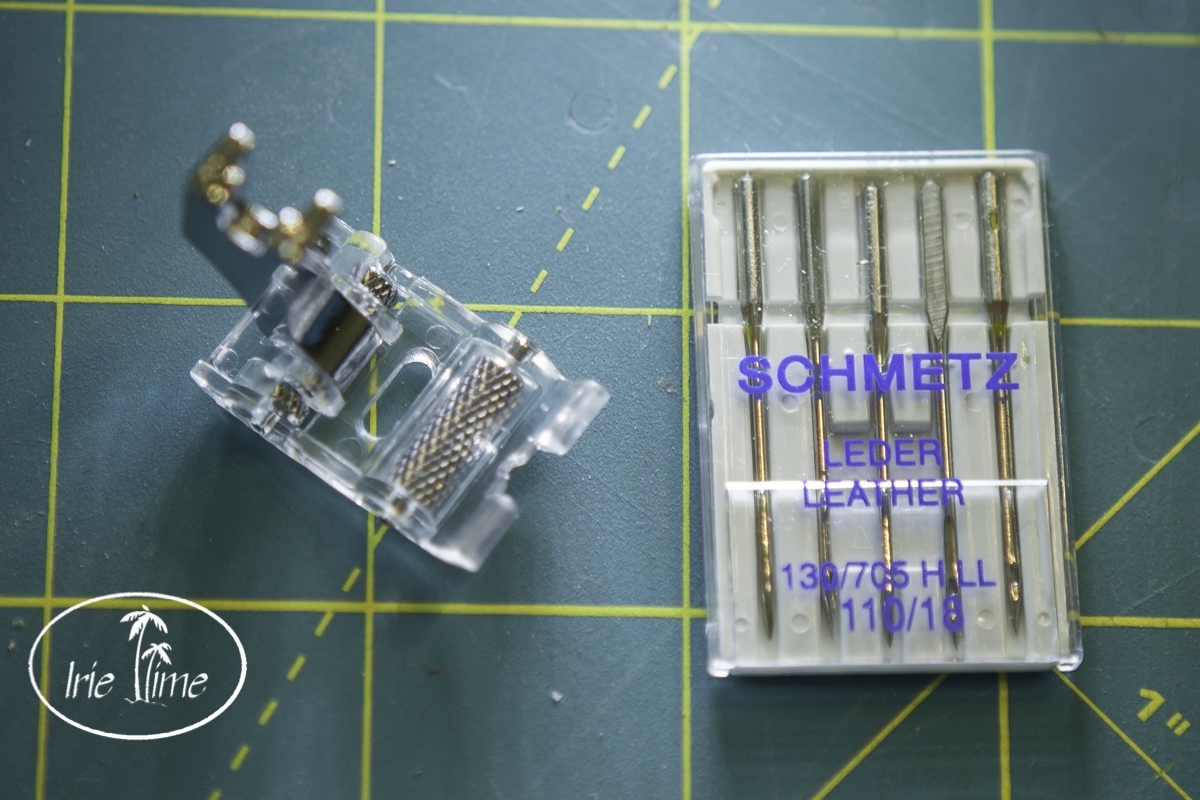

The idea was to make covers for the legs which could be stored on the legs of the tripod. As a result, the covers couldn’t be too long. To get the sizing of the pieces, I squared up the neoprene by lining it up on my cutting mat and making sure the edges were square. Neoprene and scissors do not get along. You will avoid pulling the fabric and getting wonky lines by using a rotary cutter.

Once the fabric was squared up, I wrapped it around the leg of the tripod and added roughly 3/8″ for seam allowance. I used the widest part of the tripod leg so that I could be sure it could be pulled all the way up. I made them a few inches longer in length than the stored leg size, with the idea that I could fold over the extra length for storage. I used strips that were 5″ wide by 19″ long for my Gitzo Mountaineer 0532 tripod. If I was doing it again, I would have made the strips a bit narrower for a more snug fit, probably 4-1/2″ wide.

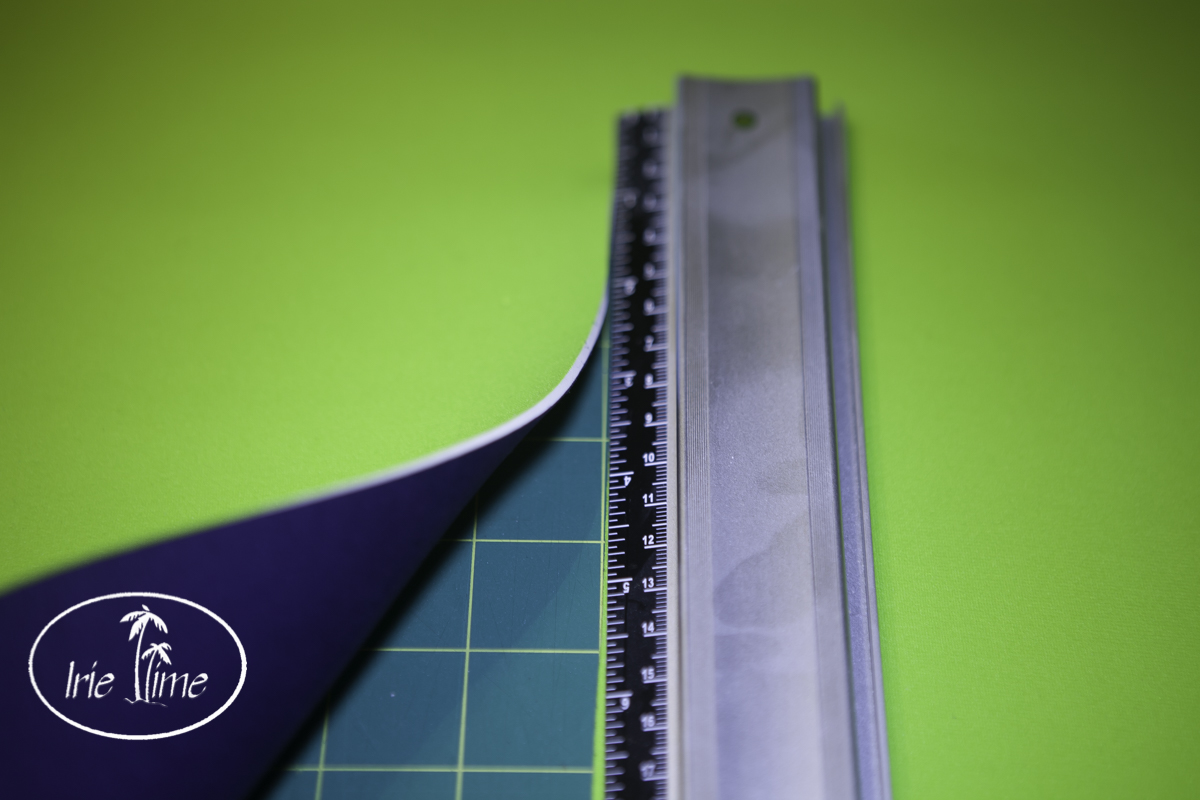

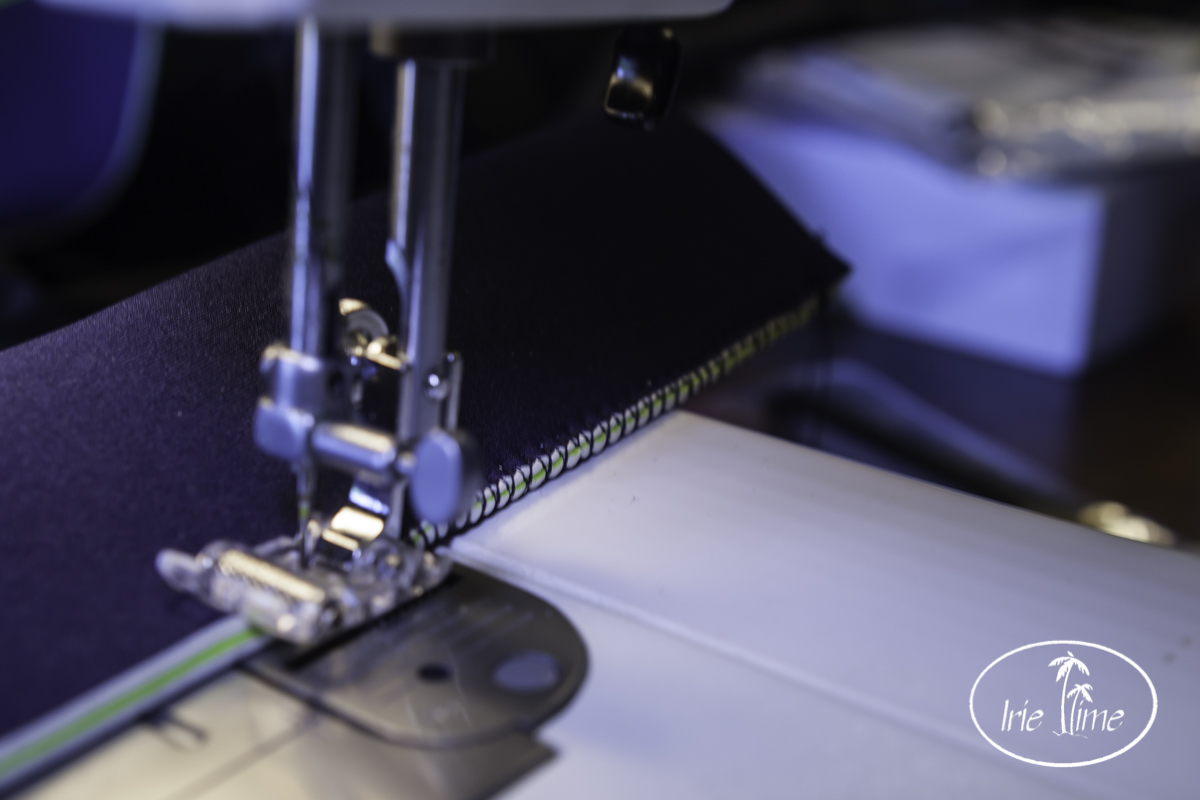

It took a bit of trial and error with scraps of fabric to find out what stitch, and what tension worked best. I used a roller foot so that the fabric would move through more easily while stitching. I used a standard overlock stitch in the longest and largest stitch available, and jacked up the tension as high as it would go.

Just a note on my sewing machine – – it is nothing fancy. I purchased this machine 15 years ago or so and I bought it because it was a very basic machine, used to teach people to sew. It’s nothing special, proving that you do not need any exceptional tools for a project like this one.

Given that I was making what were essentially long thin tubes, I really didn’t have many options for stitching. I would have preferred to glue the cut edges abutting one another with Aquaseal and then after the glue dried, do a stitch over the top to reinforce the seam. That would leave a nice flat seam like you see on wetsuits. That wasn’t an option here because there was no way to use that stitch on a long thin tube, so I used an overlock stitch. I wanted to use Aquaseal on the seam to keep the water and sand out as much as possible, so I made two samples. On the first sample, I glued first. With Aquaseal, you glue each side, wait 10 minutes, and then press them together, leaving them to cure. Then I could overstitch the glued seam. On the other sample, I overstitched the seam, and then spread a thin line of Aguaseal on the inside of the seam. Of the two options, I went with the second. Glueing first leaves a very wide seam, while I could keep the seam narrow if I sewed first and then just applied the glue thinly along the seam line. Another option would be to glue, then trim down the glued seam, and then sew. Whatever option you choose, be sure to use Aquaseal in a well-ventilated area.

Once the glue is completely cured, fold over the tops and slide them on you tripod legs. It takes very little fabric and the sewing is relatively easy once you get the tension set correctly. It’s a quick little project to provide a bit more protection to your very expensive tripod!

For more photography tips and gear information, browse our posts here:

[the_grid name=”PhotoTips”]